Mbali zambiri zazida zatsopano zochepetsera mphamvundizida zamagalimotoPulojekitiyi imafuna kutsukidwa kwa mano pambuyo popukutidwa, zomwe zingawononge ubwino wa pamwamba pa dzino, komanso kukhudza momwe NVH imagwirira ntchito. Pepalali limaphunzira za kuuma kwa pamwamba pa dzino la mano m'njira zosiyanasiyana zotsukidwa kwa mano ndi ziwalo zosiyanasiyana asanayambe komanso atatha kutsukidwa. Zotsatira zake zikusonyeza kuti kutsukidwa kwa mano kudzawonjezera kuuma kwa pamwamba pa dzino, komwe kumakhudzidwa ndi makhalidwe a ziwalo, magawo a njira zotsukidwa kwa mano ndi zinthu zina; Pansi pa mikhalidwe yomwe ilipo yopangira gulu, kuuma kwakukulu kwa pamwamba pa dzino pambuyo potsukidwa kwa mano ndi nthawi 3.1 kuposa asanayambe kutsukidwa. Mphamvu ya kuuma kwa pamwamba pa dzino pa magwiridwe antchito a NVH ikukambidwa, ndipo njira zowongolera kuuma kwa mano pambuyo potsukidwa kwa mano zikuperekedwa.

Pansi pa maziko omwe ali pamwambapa, pepalali likukambirana mbali zitatu izi:

Mphamvu ya njira yodulira mano pogwiritsa ntchito mikwingwirima pa kuuma kwa pamwamba pa dzino;

Mlingo wokulitsa wa kupyoza kwa mano pa kuuma kwa dzino pansi pa mikhalidwe yomwe ilipo yopangira gulu;

Zotsatira za kuwonjezeka kwa kukhwinya kwa pamwamba pa dzino pa ntchito ya NVH ndi njira zowongolera kukhwinya pambuyo pochotsa mano.

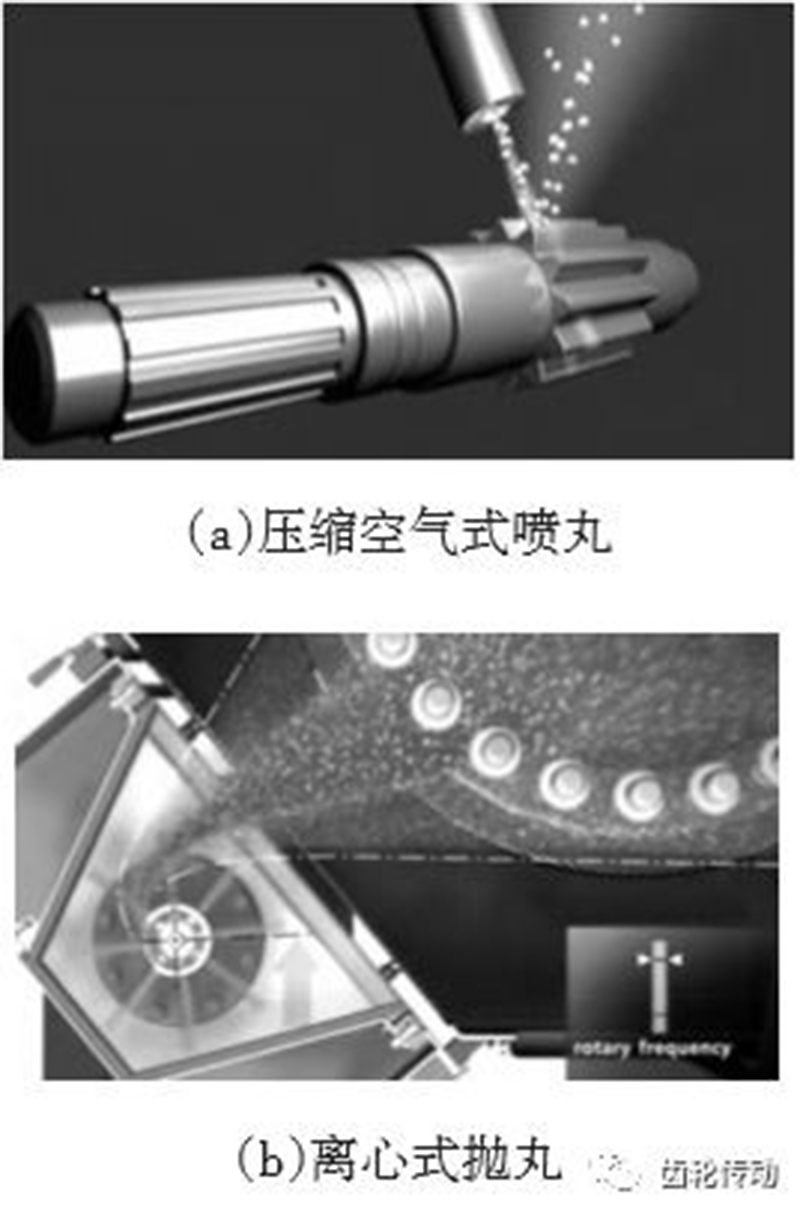

Kuboola kwa zipolopolo kumatanthauza njira yomwe zipolopolo zambiri zazing'ono zolimba kwambiri komanso kuyenda mwachangu zimagunda pamwamba pa ziwalo. Pansi pa kugwedezeka kwa zipolopolo mwachangu kwambiri, pamwamba pa gawolo padzapanga mabowo ndipo kusintha kwa pulasitiki kudzachitika. Mabungwe ozungulira mabowowo adzalimbana ndi kusinthaku ndikupanga kupsinjika kotsalira. Kulumikizana kwa mabowo ambiri kudzapanga gawo lofanana la kupsinjika kotsalira pamwamba pa gawolo, motero kukulitsa mphamvu ya kutopa kwa gawolo. Malinga ndi njira yopezera liwiro lalikulu ndi kuwombera, kuboola kwa zipolopolo nthawi zambiri kumagawidwa m'magulu awiri: mpweya wopanikizika woboola ndi centrifugal shot peening, monga momwe zasonyezedwera pa Chithunzi 1.

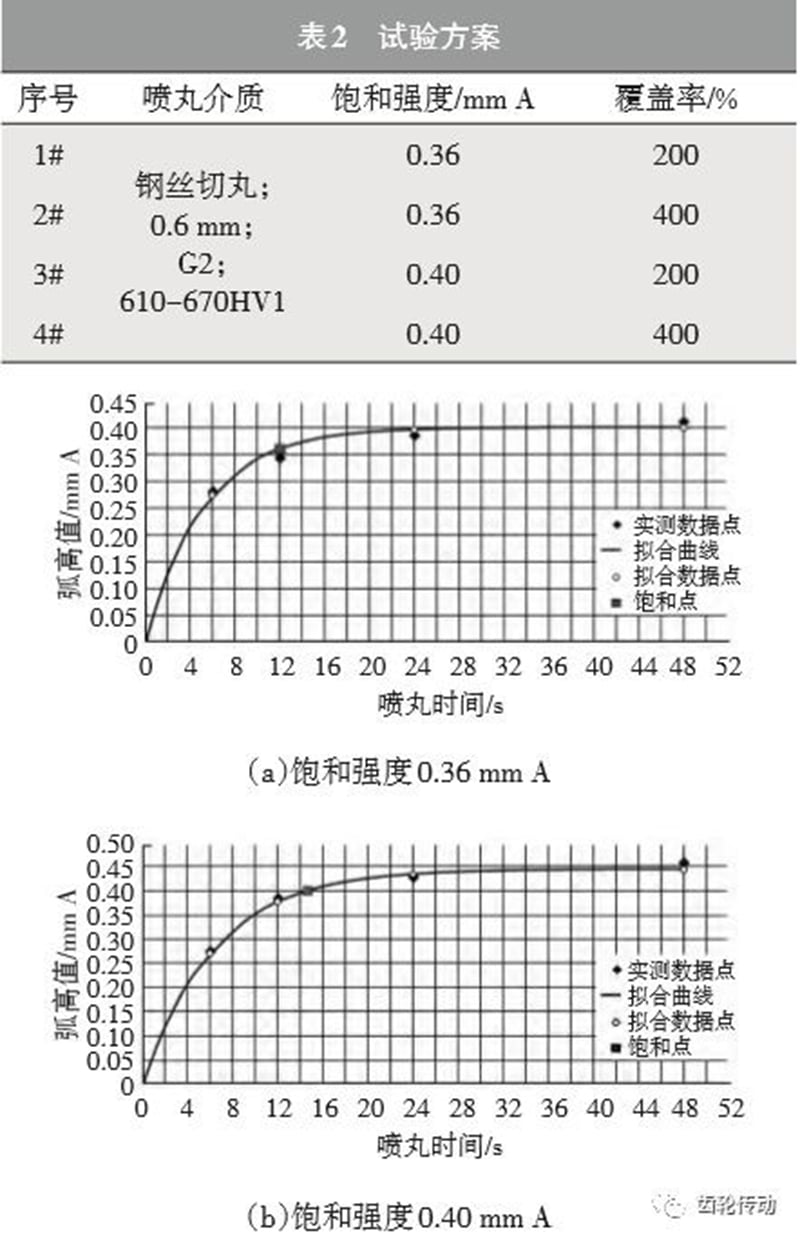

Kutulutsa mpweya wopanikizika kumatenga mpweya wopanikizika ngati mphamvu kuti upopere mfuti kuchokera ku mfuti; Kutulutsa mfuti kwa centrifugal kumagwiritsa ntchito injini kuyendetsa impeller kuti izungulire mwachangu kuti iponye mfutiyo. Magawo ofunikira a njira yotulutsira mfuti ndi monga mphamvu yokwanira, kuphimba ndi mawonekedwe apakati otulutsira mfuti (zinthu, kukula, mawonekedwe, kuuma). Mphamvu yokhuta ndi gawo lofotokozera mphamvu yotulutsira mfuti, yomwe imawonetsedwa ndi kutalika kwa arc (monga digiri yopindika ya chidutswa choyesera cha Almen pambuyo potulutsa mfuti); Kuchuluka kwa kuphimba kumatanthauza chiŵerengero cha malo ophimbidwa ndi dzenje pambuyo potulutsa mfuti kudera lonse la malo otulutsira mfuti; Zida zotulutsira mfuti zomwe zimagwiritsidwa ntchito kwambiri zimaphatikizapo chitsulo chodulira waya, chitsulo chopangidwa ndi chitsulo, ceramic shot, galasi shot, ndi zina zotero. Kukula, mawonekedwe ndi kuuma kwa zida zotulutsira mfuti ndi zamitundu yosiyanasiyana. Zofunikira zonse za njira zoyendetsera zida zotumizira zikuwonetsedwa mu Gome 1.

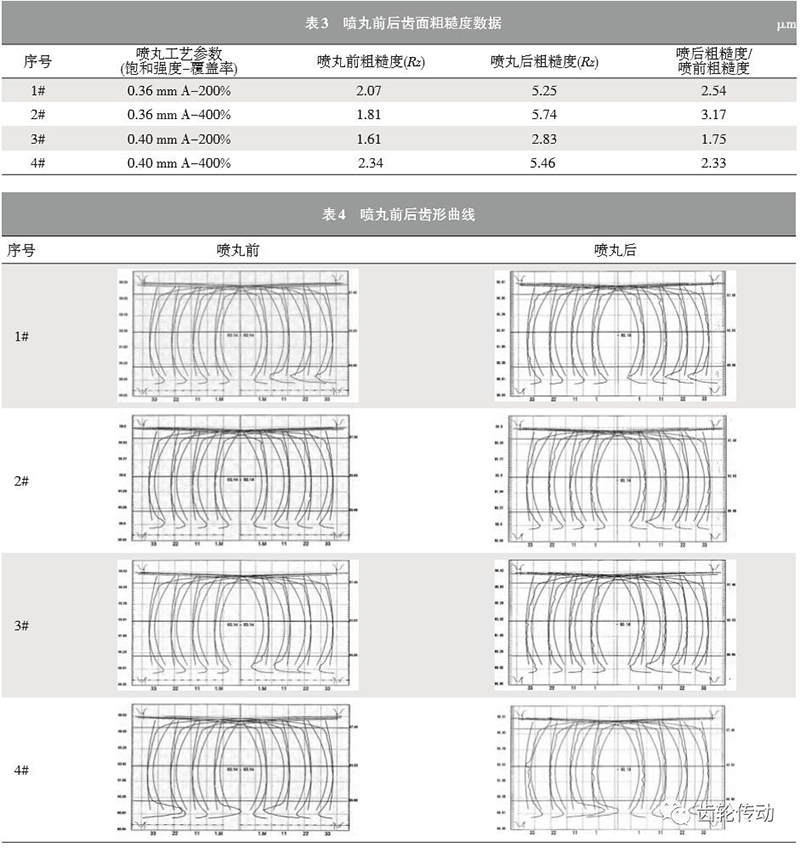

Gawo loyesera ndi giya lapakati la shaft 1/6 la pulojekiti yosakanikirana. Kapangidwe ka giya kakuwonetsedwa pa Chithunzi 2. Pambuyo popera, kapangidwe ka pamwamba pa dzino ndi Giredi 2, kuuma kwa pamwamba ndi 710HV30, ndipo kuya kwa gawo lolimba bwino ndi 0.65mm, zonse mogwirizana ndi zofunikira zaukadaulo. Kukhwima kwa pamwamba pa dzino musanatulutse mano kwawonetsedwa pa Gome 3, ndipo kulondola kwa mbiri ya dzino kwawonetsedwa pa Gome 4. Zitha kuwoneka kuti kukhwima kwa pamwamba pa dzino musanatulutse mano ndi kwabwino, ndipo kupindika kwa mbiri ya dzino ndi kosalala.

Dongosolo loyesera ndi magawo oyesera

Makina opopera mpweya opopera pogwiritsa ntchito mpweya wopopera amagwiritsidwa ntchito poyesa. Chifukwa cha mikhalidwe yoyesera, n'zosatheka kutsimikizira momwe zinthu zopopera pogwiritsa ntchito mfuti zimakhudzira (zinthu, kukula, kuuma). Chifukwa chake, makhalidwe a chopopera pogwiritsa ntchito mfuti amakhala osasintha muyeso. Mphamvu yokha ya kukhuta ndi kuphimba mano okhwima pambuyo popopera pogwiritsa ntchito mfuti ndiyo yotsimikizika. Onani Gome 2 kuti mudziwe njira yoyesera. Njira yeniyeni yodziwira magawo oyesera ndi iyi: jambulani mzere wopopera (Chithunzi 3) kudzera mu mayeso a Almen coupon kuti mudziwe malo opopera, kuti mutseke kuthamanga kwa mpweya wopopera pogwiritsa ntchito mpweya wopopera, kuyenda kwa chitsulo, liwiro losuntha kwa nozzle, mtunda wa nozzle kuchokera ku ziwalo ndi zida zina.

zotsatira za mayeso

Deta ya kuuma kwa pamwamba pa dzino pambuyo pochotsa mano ikuwonetsedwa mu Gome 3, ndipo kulondola kwa mawonekedwe a dzino kukuwonetsedwa mu Gome 4. Zitha kuwoneka kuti pansi pa mikhalidwe inayi yochotsera mano, kuuma kwa pamwamba pa dzino kumawonjezeka ndipo kupindika kwa mawonekedwe a dzino kumakhala kopindika komanso kotambasuka pambuyo pochotsa mano. Chiŵerengero cha kuuma pambuyo pochotsa mano ndi kuuma musanachotse mano chimagwiritsidwa ntchito kufotokozera kukula kwa kuuma (Gome 3). Zitha kuwoneka kuti kukula kwa kuuma kumasiyana pansi pa mikhalidwe inayi yogwiritsira ntchito.

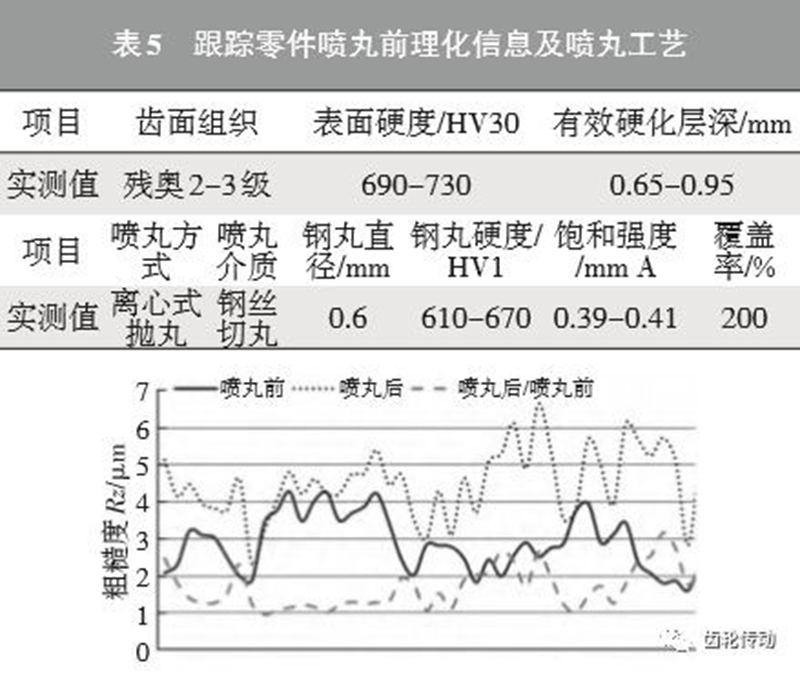

Kutsata Magulu a Kukula kwa Kuuma kwa Mano Pogwiritsa Ntchito Kuboola Mzere

Zotsatira za mayeso mu Gawo 3 zikusonyeza kuti kukhwima kwa pamwamba pa dzino kumawonjezeka mosiyanasiyana pambuyo pochotsa mano pogwiritsa ntchito njira zosiyanasiyana. Pofuna kumvetsetsa bwino kukulitsa kwa kutsuka mano pa kukhwima kwa mano ndikuwonjezera chiwerengero cha zitsanzo, zinthu 5, mitundu 5 ndi zigawo 44 zonse, zidasankhidwa kuti zitsatire kukhwima asanayambe komanso atatulutsa mano motsatira njira yopangira ma batch yochotsera mano. Onani Gome 5 kuti mudziwe zambiri zakuthupi ndi zamankhwala komanso zambiri za njira yochotsera mano pa ziwalo zomwe zatsatiridwa pambuyo popukuta zida. Deta yokhwima ndi kukula kwa mano kutsogolo ndi kumbuyo asanayambe kutulutsa mano ikuwonetsedwa mu Chithunzi 4. Chithunzi 4 chikuwonetsa kuti kukhwima kwa mano asanayambe kutulutsa mano ndi Rz1.6 μ m-Rz4.3 μ m; Pambuyo potulutsa mano, kukhwima kumawonjezeka, ndipo kuchuluka kwa kufalikira ndi Rz2.3 μ m-Rz6.7 μ m; Kukhwima kwakukulu kumatha kukulitsidwa mpaka nthawi 3.1 asanayambe kutulutsa mano.

Zinthu zomwe zimayambitsa kuuma kwa pamwamba pa dzino pambuyo pochotsa mano

Kuchokera pa mfundo yoti munthu atulutse mano m'manja, tingaone kuti kuuma kwambiri komanso kuthamanga kwambiri kwa kuwombera kumasiya mabowo osawerengeka pamwamba pa gawo, zomwe zimapangitsa kuti munthu asamavutike kwambiri. Nthawi yomweyo, mabowo amenewa adzawonjezera kuuma kwa pamwamba. Makhalidwe a ziwalo zisanatulutse mano m'manja ndi magawo a njira yotulutsira mano m'manja zidzakhudza kuuma kwa mano pambuyo potulutsa mano m'manja, monga momwe zalembedwera mu Gome 6. Mu Gawo 3 la pepalali, pansi pa mikhalidwe inayi ya njira, kuuma kwa mano pambuyo potulutsa mano m'manja kumawonjezeka mpaka madigiri osiyanasiyana. Mu mayesowa, pali zinthu ziwiri zomwe zimasintha, zomwe ndi, kuuma kwa mano m'manja ndi magawo a njira (mphamvu yokhutitsa kapena kuphimba), zomwe sizingathe kudziwa bwino ubale womwe ulipo pakati pa kuuma kwa mano pambuyo potulutsa mano ndi chinthu chilichonse chomwe chimakhudza. Pakadali pano, akatswiri ambiri achita kafukufuku pa izi, ndipo apereka chitsanzo cholosera za kuuma kwa nkhope pambuyo potulutsa mano kutengera kuyerekezera kwa zinthu zochepa, komwe kumagwiritsidwa ntchito kuneneratu kuchuluka kwa kuuma kwa mano m'manja mwa munthu ...

Kutengera ndi zomwe zachitika komanso kafukufuku wa akatswiri ena, njira zosiyanasiyana zomwe zimakhudzira zinthu zitha kuganiziridwa monga momwe zasonyezedwera mu Gome 6. Zitha kuwoneka kuti kuuma pambuyo pochotsa chotupa kumakhudzidwa kwambiri ndi zinthu zambiri, zomwe ndi zinthu zofunika kwambiri zomwe zimakhudza kupsinjika kotsalira. Pofuna kuchepetsa kuuma pambuyo pochotsa chotupa poganizira kuti pali kupsinjika kotsalira, mayeso ambiri akufunika kuti nthawi zonse pakhale kusakaniza kwa magawo.

Mphamvu ya kuuma kwa pamwamba pa dzino pa magwiridwe antchito a NVH a dongosolo

Zigawo za zida zili mu dongosolo lotumizira mphamvu, ndipo kuuma kwa pamwamba pa dzino kudzakhudza magwiridwe antchito awo a NVH. Zotsatira za kafukufuku zikuwonetsa kuti pansi pa katundu ndi liwiro lomwelo, kuuma kwa pamwamba kumakhala kwakukulu, kugwedezeka ndi phokoso la dongosololi kumakhala kwakukulu; Pamene katundu ndi liwiro zikuwonjezeka, kugwedezeka ndi phokoso zimawonjezeka momveka bwino.

M'zaka zaposachedwapa, mapulojekiti a zochepetsera mphamvu zatsopano awonjezeka mofulumira, ndipo akuwonetsa chitukuko cha liwiro lalikulu komanso mphamvu yayikulu. Pakadali pano, mphamvu yayikulu ya chochepetsera mphamvu chathu chatsopano ndi 354N · m, ndipo liwiro lalikulu ndi 16000r/min, lomwe lidzawonjezeka kufika pa 20000r/min mtsogolomu. Pansi pa mikhalidwe yotereyi yogwirira ntchito, mphamvu ya kuwonjezeka kwa kuuma kwa pamwamba pa mano pa magwiridwe antchito a NVH a dongosololi iyenera kuganiziridwa.

Njira zowongolera mano okhwima pambuyo pochotsa mano m'mano

Njira yochotsera mano pambuyo pochotsa mano ingathandize kulimbitsa mphamvu ya kutopa kwa pamwamba pa dzino la giya komanso mphamvu ya kutopa yopindika ya muzu wa dzino. Ngati njira iyi iyenera kugwiritsidwa ntchito chifukwa cha mphamvu pakupanga zida, kuti tiganizire momwe NVH imagwirira ntchito, kuuma kwa pamwamba pa dzino la giya pambuyo pochotsa mano kungawongoleredwe kuchokera ku zinthu zotsatirazi:

a. Konzani bwino magawo a njira yodulira mano, ndikuwongolera kukulitsa kwa kuuma kwa pamwamba pa dzino pambuyo podulira mano poganizira kuti pali kupsinjika kotsalira. Izi zimafuna mayeso ambiri a njira, ndipo kusinthasintha kwa njira sikokwanira.

b. Njira yopangira utoto wophatikizana imagwiritsidwa ntchito, ndiko kuti, pambuyo poti utoto wothira utoto wa nthawi zonse utatha, utoto wina umawonjezeredwa. Mphamvu yowonjezera ya utoto wothira utoto nthawi zambiri imakhala yaying'ono. Mtundu ndi kukula kwa zipangizo zothira utoto zimatha kusinthidwa, monga utoto wa ceramic, utoto wagalasi kapena utoto wachitsulo wodulidwa ndi waya wocheperako.

c. Pambuyo pochotsa mano, njira monga kupukuta pamwamba pa mano ndi kuyeretsa mano momasuka zimawonjezedwa.

Mu pepalali, kuuma kwa pamwamba pa dzino la mano pazochitika zosiyanasiyana za njira yochotsera mano ndi ziwalo zosiyanasiyana asanayambe ndi pambuyo pake achotsa mano, ndipo mfundo zotsatirazi zaperekedwa kutengera mabuku:

◆ Kuboola mano kudzawonjezera kuuma kwa pamwamba pa dzino, komwe kumakhudzidwa ndi mawonekedwe a ziwalo zisanayambe kuboola mano, magawo a njira yoboola mano ndi zinthu zina, ndipo zinthu izi ndi zinthu zofunika kwambiri zomwe zimakhudza kupsinjika kotsalira kwa mano;

◆ Malinga ndi momwe zinthu zilili panopa, kuuma kwa pamwamba pa dzino pambuyo pochotsa mano ndi nthawi 3.1 kuposa pamene mano achotsedwa mano asanachotse mano;

◆ Kuwonjezeka kwa kuuma kwa pamwamba pa dzino kudzawonjezera kugwedezeka ndi phokoso la dongosolo. Mphamvu ndi liwiro zikakula, kugwedezeka ndi phokoso zimaonekera kwambiri;

◆ Kukhwima kwa pamwamba pa dzino pambuyo pochotsa mano kungawongoleredwe mwa kukonza magawo a njira yochotsera mano, kuchotsa mano ophatikizana, kuwonjezera kupukuta kapena kupukuta kwaulere pambuyo pochotsa mano, ndi zina zotero. Kukonza bwino magawo a njira yochotsera mano akuyembekezeka kuwongolera kukulitsa kwa kuuma mpaka pafupifupi nthawi 1.5.

Nthawi yotumizira: Novembala-04-2022