Gleasonmagiya ozungulira a bevelndi mtundu wapadera wa zida za bevel zomwe zimapangidwa kuti zitumize mphamvu pakati pa ma shaft olumikizana, nthawi zambiri pa ngodya ya madigiri 90. Chomwe chimapangitsa dongosolo la Gleason kukhala losiyana ndi momwe limagwirira ntchito ndi njira yake yapadera yopangira mano, zomwe zimapangitsa kuti liziyenda bwino, mphamvu yamphamvu kwambiri, komanso kugwira ntchito chete. Zida zimenezi zimagwiritsidwa ntchito kwambiri mu magalimoto, mafakitale, ndi ndege komwe kudalirika ndi kulondola ndikofunikira kwambiri.

Dongosolo la Gleason linapangidwa kuti liwongolere bwino pa nthawi yokhazikika komanso yokhazikika.magiya a zerol bevelmwa kuyambitsa dzino lopindika, looneka ngati lozungulira. Kapangidwe kameneka kamalola kuti mano azigwirana pang'onopang'ono, kuchepetsa phokoso ndi kugwedezeka pamene kumalola liwiro lalikulu lozungulira ndi mphamvu yonyamula katundu. Kapangidwe kameneka kamathandizanso kuti pakhale chiŵerengero chokhudzana ndi kukhudzana ndi mphamvu ya pamwamba, kuonetsetsa kuti mphamvu imatumizidwa bwino pansi pa katundu wolemera kapena wosinthasintha.

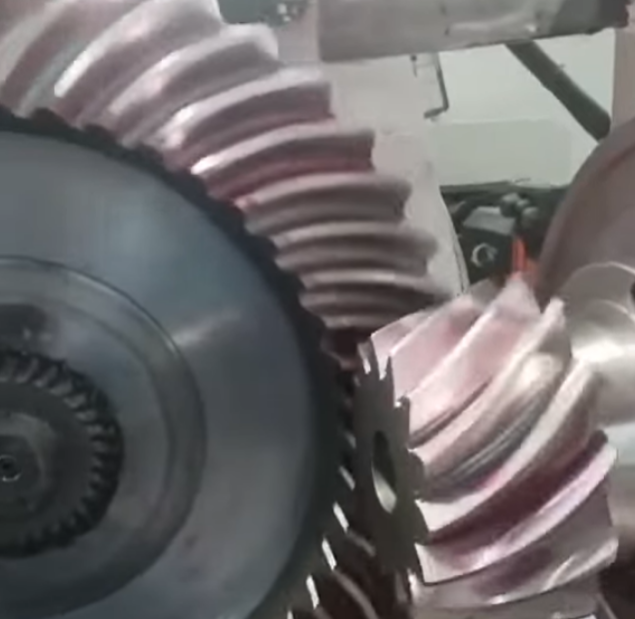

Chida chilichonse cha Gleason spiral bevel giya chimakhala ndi pinion ndi giya yolumikizirana, yopangidwa ndi geometry yofanana. Njira yopangirayi ndi yapadera kwambiri. Imayamba ndi kupangira kapena kuponyera molondola zitsulo zopanda kanthu, monga 18CrNiMo7-6, kutsatiridwa ndi kudula kosalala, kuyika chitoliro, kapena kupanga mawonekedwe oyamba a giya. Njira zapamwamba monga 5-axis machining, skiving, ndi kudula kolimba zimatsimikizira kulondola kwapamwamba komanso kumaliza bwino kwa pamwamba. Pambuyo pa chithandizo cha kutentha monga carburization (58–60 HRC), magiya amadutsa kapena kupukutidwa kuti akwaniritse bwino ma mesh pakati pa pinion ndi giya.

Maonekedwe a magiya a Gleason spiral bevel amatanthauzidwa ndi magawo angapo ofunikira—ngodya yozungulira, ngodya yokakamiza, mtunda wa pitch cone, ndi m'lifupi mwa nkhope. Magawo awa amawerengedwa bwino kuti atsimikizire kuti mano ali ndi mawonekedwe oyenera komanso kugawa katundu. Pakuwunika komaliza, zida monga makina oyezera (CMM) ndi kusanthula kwa kulumikizana kwa mano (TCA) zimatsimikizira kuti seti ya magiya ikukwaniritsa kalasi yolondola ya DIN 6 kapena ISO 1328-1.

Ikugwira ntchito, Gleason spiralmagiya a bevelMano amenewa amapereka mphamvu zambiri komanso magwiridwe antchito okhazikika ngakhale pakakhala zovuta. Mano opindika amapereka kukhudzana kosalekeza, kuchepetsa kupsinjika ndi kuwonongeka. Izi zimapangitsa kuti akhale abwino kwambiri pamagalimoto osiyanasiyana, ma gearbox a magalimoto, makina olemera, makina oyendetsa magalimoto apamadzi, ndi zida zamagetsi. Kuphatikiza apo, kuthekera kosintha mawonekedwe a mano ndi mtunda woyikira kumathandiza mainjiniya kukonza kapangidwe kake kuti kagwirizane ndi mphamvu yeniyeni, liwiro, ndi malo.

Giya lozungulira la bevel la mtundu wa Gleason — tebulo lowerengera makiyi

| Chinthu | Fomula / Kufotokozera | Zosintha / Zolemba |

|---|---|---|

| Magawo olowera | (z_1,\ z_2,\ m_n,\ \alpha_n,\ \Sigma,\ b,\ T) | mano a pinion/giya (z); gawo labwinobwino (m_n); ngodya ya kupanikizika kwabwinobwino (\alpha_n); ngodya ya shaft (\Sigma); m'lifupi mwa nkhope (b); mphamvu yotumizira (T). |

| Chiyerekezo (avereji) m'mimba mwake | (d_i = z_i , m_n) | i = 1 (pinion), 2 (giya). Avereji/mamita oyerekeza mu gawo labwinobwino. |

| Ma angles a phula (khoni) | (\delta_1,\ \delta_2) kotero kuti (\delta_1+\delta_2=\Sigma) ndi (\dfrac{\sin\delta_1}{d_1}=\dfrac{\sin\delta_2}{d_2}) | Konzani ngodya za koni zomwe zimagwirizana ndi kuchuluka kwa dzino ndi ngodya ya shaft. |

| Mtunda wa koni (mtunda wa pamwamba pa phiri) | (R = \dfrac{d_1}{2\sin\delta_1} = \dfrac{d_2}{2\sin\delta_2}) | Mtunda wochokera pamwamba pa kononi kupita ku bwalo lozungulira umayesedwa motsatira generatrix. |

| Kuzungulira kwa mawu (kwabwinobwino) | (p_n = \pi m_n) | Kuyimitsa kolunjika pagawo labwinobwino. |

| Gawo lozungulira (pafupifupi) | (m_t = \dfrac{m_n}{\cos\beta_n}) | (\beta_n) = ngodya yozungulira yachibadwa; imasintha pakati pa magawo abwinobwino ndi opingasa ngati pakufunika. |

| Ngodya yozungulira (ubale wapakati/wopingasa) | (\tan\beta_t = \tan\beta_n \cos\delta_m) | (\delta_m) = ngodya yapakati ya koni; gwiritsani ntchito ma transforms pakati pa ngodya zachizolowezi, zopingasa, ndi zapakati zozungulira. |

| Malangizo a kukula kwa nkhope | (b = k_b , m_n) | (k_b) nthawi zambiri amasankhidwa kuyambira 8 mpaka 20 kutengera kukula ndi kagwiritsidwe ntchito; funsani akatswiri opanga mapangidwe kuti mudziwe mtengo wake weniweni. |

| Zowonjezera (apakati) | (a \pafupifupi m_n) | Kuyerekeza kwabwino kwa mano; gwiritsani ntchito matebulo enieni a kuchuluka kwa mano kuti mupeze mfundo zenizeni. |

| Kunja (nsonga) m'mimba mwake | (d_{o,i} = d_i + 2a) | i = 1,2 |

| Muzu wa m'mimba mwake | (d_{f,i} = d_i – 2h_f) | (h_f) = dedendum (kuchokera ku kuchuluka kwa zida zamagetsi). |

| Kukhuthala kwa dzino lozungulira (pafupifupi) | (s \pafupifupi \dfrac{\pi m_n}{2}) | Kuti mugwiritse ntchito mawonekedwe a bevel, gwiritsani ntchito makulidwe oyenera kuchokera pa matebulo a mano kuti mutsimikizire kulondola. |

| Mphamvu yozungulira pa bwalo la mlengalenga | (F_t = \dfrac{2T}{d_p}) | (T) = torque; (d_p) = dayamita ya pitch (gwiritsani ntchito mayunitsi ogwirizana). |

| Kupsinjika maganizo (kosavuta) | (\sigma_b = \dfrac{F_t \cdot K_O \cdot K_V}{b \cdot m_n \cdot Y}) | (K_O) = overload factor, (K_V) = dynamic factor, (Y) = form factor (mawonekedwe opindika). Gwiritsani ntchito equation yonse ya AGMA/ISO bending pakupanga. |

| Kupsinjika kwa kukhudzana (mtundu wa Hertz, wosavuta) | (\sigma_H = C_H \sqrt{\dfrac{F_t}{d_p , b} \cdot \dfrac{1}{\frac{1-\nu_1^2}{E_1}+\frac{1-\nu_2^2}{E_2}}}) | (C_H) geometry constant, (E_i,\nu_i) material elastic moduli ndi Poisson ratios. Gwiritsani ntchito ma equation onse okhudzana ndi kupsinjika kuti mutsimikizire. |

| Chiŵerengero cha kukhudzana (chachikulu) | (\varepsilon = \dfrac{\text{arc of action}}{\text{base pitch}}) | Pa magiya a bevel, werengani pogwiritsa ntchito mawonekedwe a pitch cone ndi ngodya yozungulira; nthawi zambiri imayesedwa ndi matebulo kapena mapulogalamu opangidwa ndi magiya. |

| Chiwerengero chenicheni cha mano | (z_v \pafupifupi \dfrac{d}{m_t}) | Zothandiza poyang'ana kukhudzana/kuchepetsa; (m_t) = gawo lopingasa. |

| Kuwunika mano pang'ono / kudulidwa pang'ono | Gwiritsani ntchito mano ochepa kutengera ngodya yozungulira, ngodya yopanikizika, ndi kuchuluka kwa mano | Ngati (z) ili pansi pa chocheperako, kudulidwa pang'ono kapena zida zapadera zimafunika. |

| Makonzedwe a makina/zodulira (gawo la kapangidwe) | Dziwani ma angles a mutu wa cutter, kuzungulira kwa cradle ndi indexing kuchokera ku geometry ya makina a zida | Makonzedwe awa amachokera ku geometry ya magiya ndi makina odulira; tsatirani njira yogwiritsira ntchito makina/zida. |

Ukadaulo wamakono wopanga zinthu, monga makina odulira ndi kupukusira zida za CNC bevel, umatsimikizira kuti zinthu zimayenda bwino komanso zimasinthasintha. Mwa kuphatikiza kapangidwe kothandizidwa ndi makompyuta (CAD) ndi simulation, opanga amatha kuchita reverse engineering ndi virtual examination asanapange zenizeni. Izi zimachepetsa nthawi yotsogolera komanso mtengo wake pamene akukonza kulondola komanso kudalirika.

Mwachidule, magiya a Gleason spiral bevel akuyimira kuphatikiza kwabwino kwa geometry yapamwamba, mphamvu ya zinthu, ndi kulondola kwa kupanga. Kutha kwawo kupereka mphamvu yosalala, yogwira ntchito bwino, komanso yolimba kwawapanga kukhala gawo lofunikira kwambiri m'makina amakono oyendetsa. Kaya amagwiritsidwa ntchito m'magawo a magalimoto, mafakitale, kapena ndege, magiya awa akupitilizabe kufotokoza luso la kuyenda ndi magwiridwe antchito amakina.

Nthawi yotumizira: Okutobala-24-2025